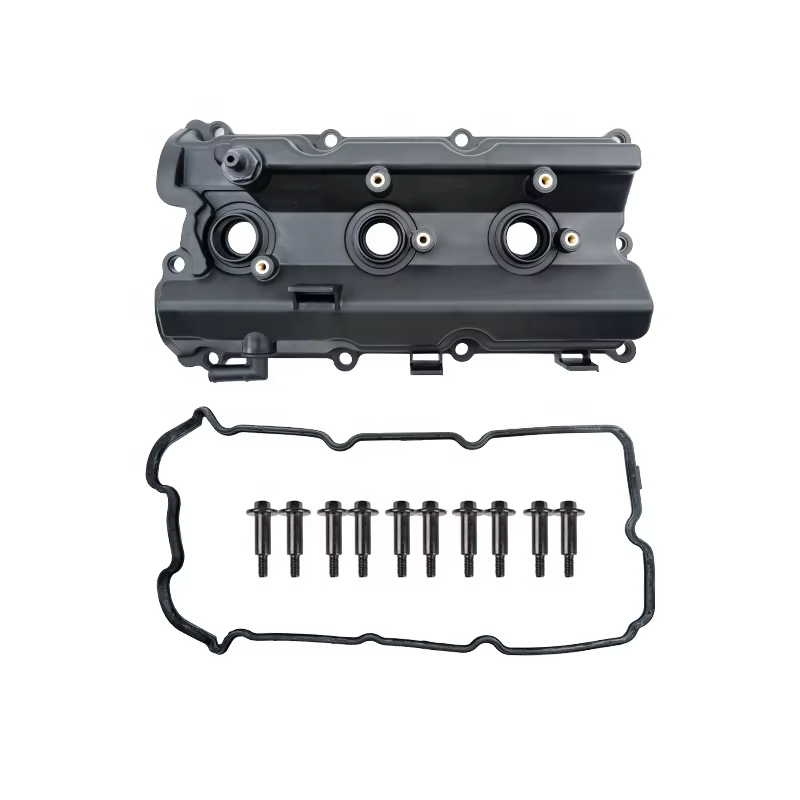

The rocker cover, sometimes called a valve cover, sits right on top of those engine cylinder heads. Its main job? Stop oil from leaking out while keeping dirt and other junk away from the valve train components. Without this seal, the whole system struggles to maintain adequate oil pressure and proper circulation throughout the engine. When that happens, parts don't get lubricated consistently and heat builds up faster than it should. If a cover gets damaged or worn out, engines can suffer serious problems. Studies show worn covers might cause up to 68% more wear on camshafts and lifters over time, per research published by SAE International last year. These covers do more than just keep things clean though. They actually help reduce engine noise levels and trap those pesky blow-by gases inside, making engines run cleaner and more efficiently overall. Strong construction matters too because engines need these covers to hold up during tough driving conditions without failing prematurely.

The precision of manufacturing plays a big role in how well a rocker cover holds up against the constant heating and cooling cycles plus all that engine vibration. When materials aren't good enough or when casting isn't consistent throughout production runs, we often see problems like warping or tiny cracks forming. These issues lead to oil leaks, something that costs plant managers around $740,000 every year just from unexpected shutdowns according to Ponemon's research back in 2023. Top tier facilities stick with ISO 9001 certifications because they know this helps maintain those tight tolerances and keeps material properties stable across batches. Meeting regulations goes beyond just making parts last longer too. Plants need to pass strict EPA and CARB tests for emissions by doing thorough leak checks on everything. Parts that don't make the grade might bring down fines or even force product recalls worth over 12% of yearly profits. Working with factories that have proper certifications means better tracking of raw materials, clearer records about quality checks, and ultimately less financial risk overall.

| Quality Factor | Durability Impact | Compliance Requirement |

|---|---|---|

| Material Grade | Resists 300°C+ temperatures | Meets RoHS/REACH standards |

| Sealing Surface Precision | Prevents 99.7% of oil leaks | Validated via ASTM F3162 |

| Corrosion Resistance | 5,000+ hour salt spray test | ISO 9227 certification |

The choice of material directly affects performance and compatibility—aluminum alloys provide excellent thermal conductivity, while engineered thermoplastics reduce weight without sacrificing strength. Evaluate a factory’s production capabilities by assessing:

Prioritize factories with IATF 16949 certification, which correlates with a 47% reduction in defect rates compared to non-certified facilities. Compliance should include adherence to:

Look for suppliers offering flexible customization, including:

Reliable lead times and scalable capacity are essential for maintaining smooth assembly operations. Delays can disrupt production schedules and increase inventory costs, contributing to annual losses exceeding $740k (Ponemon 2023). Assess a factory’s ability to:

Efficient international logistics depend on coordinated shipping, accurate customs documentation, and strategic warehousing. Favor suppliers with regional distribution hubs, as they often offer lower MOQs and faster restocking cycles.

| Logistics Factor | Impact on B2B Buyers | Optimal Solution |

|---|---|---|

| Port Delays | Production halts | Multi-port shipping options |

| Bulk Shipping | High freight costs | Container consolidation programs |

| Inventory Tracking | Stockout risks | Real-time digital monitoring systems |

Implementing automated inventory management systems can reduce excess stock by 18% while preventing shortages. Factories with bonded warehouses near major markets cut transit times by 40%, enabling just-in-time delivery even during peak demand.

Evaluate third-party reviews across platforms to identify consistent feedback on quality and service. In-depth case studies reveal how a factory handles complex projects, such as custom valve train components. Request references specifically for rocker cover production and verify:

Onsite audits allow direct observation of production workflows, quality checkpoints, and raw material handling—key for verifying a factory’s operational credibility. However, they involve travel costs and may only reflect curated conditions. Third-party inspectors offer objective evaluations using standardized protocols, delivering compliance reports with audit trails.

| Verification Method | Key Advantages | Limitations |

|---|---|---|

| Onsite Audits | Firsthand process evaluation | Higher cost and scheduling limits |

| Third-Party Services | Impartial, standardized reporting | Less contextual insight |

For mission-critical applications, combine both methods: use third-party inspections for routine orders and reserve onsite audits for new partnerships or major design changes.

Copyright © 2025 by Hangzhou Nansen Auto Parts Co.,Ltd. — Privacy Policy